|

Dry open blasting is available, using spendable grit or steel grit. Blasting is performed according specifications, in conformity with the currently used Standards (ISO, SSPC, and SPSS). We are able to work inside dedicated sheds, but, using our mobile equipment, onboard ships or other locations as well. |

|

|

Hi tech appliance for specialty repair works. Old paint is overheated by induction, and then easily removed mechanically. |

|

High performance paint application by spray technology is available. For this we are currently using spray pumps up till 90:1 compression rate.

Dual component pumps for application of specialty coatings, having very short pot life (such as few minutes) are also available.

We used to apply difficult to handle coatings, as glassflake epoxies, zinc silicate paints, paints for ice going ships.

At request can be applied (on a first quality blasted surfaces) a protection by thermal spray of zinc or aluminium layers, as per specifications.

|

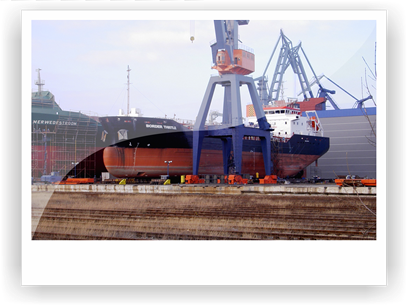

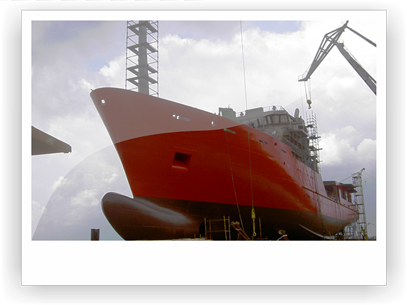

Our steel building division is able to execute steel structures, as cranes (as built in co-operation with Petrol Lavori - Italy), ship block sections (as built for supply vessels at STX Shipyards Tulcea - Romania) and many other steel structures. Works are totally independent, beginning steel purchasing and finishing with final inspection and delivery of contracted items. |

|

The Company operates up to date equipment for application of foam insulation, for urban or industrial sights.

By using a high pressure water pump (2500 bar) we are performing removing of fouling on the ship hulls under repair, before painting.

We can perform demolition works, concrete structures cutting, rebar revealing for upgrading of industrial structures.